Before forming, thermosetting plastics have the same chain structure as thermoplastics. In the forming process, thermosetting plastics form a cross-linked structure by thermal or chemical polymerization. Once the reaction is complete, the polymer molecules bond to form a three-dimensional network structure. These cross-linked bonds will prevent the sliding between the molecular chains. As a result, the thermosetting plastic becomes an immiscible and insoluble solid.

With the development of science and technology, the performance requirements of thermosetting plastics are increasing. For the problems of high brittleness and curing internal stress of thermosetting plastics (mainly epoxy and acrylate resins), Kaneka thermosetting plastic additive provides a series of solutions

How to choose the right product depends on your application. We always suggest you contact us to discuss your needs

Product

•Kaneka ® MX Impact modifier

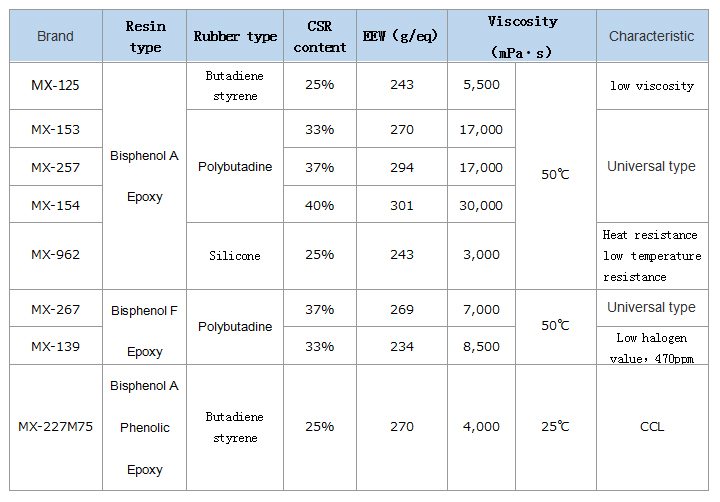

A liquid masterbatch in which nano-core-shell rubber particles (CSR) are dispersed at high concentrations (25%-40%) in liquid curable resins (mainly epoxy resins, some of which are acrylate monomers, unsaturated polyesters).

Product features:

•Complex mixing is not required because nano-sized core-shell rubber particles are pre-dispersed in the resin.

•Maintain the properties of liquid cured resins (heat resistance, rigidity, not affect the Tg, etc.) while improving fracture toughness, bond strength, surface impact resistance, low temperature toughness, cold and hot impact performance.

•Few impurities such as residual metals, suitable for electronic materials and other purposes.

•Compatible with various curing systems

Application:

•adhesives (automotive structural adhesive, aviation structural adhesive, automotive battery pack adhesive)

•composite materials (aircraft, FRP pipes, sporting goods)

•blade clamping glue

•electronic materials (semiconductor packaging materials, copper clad laminates, liquid potting)

•3D printing materials (SLA, DLP UV resin consumables)

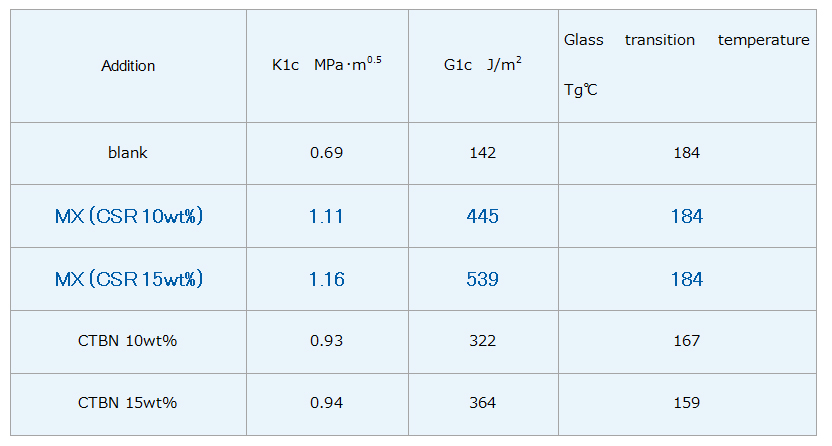

Comparison of MX and CTBN

MX can greatly improve the fracture toughness of epoxy resins without affecting their original heat resistance (without lowering the glass transition temperature Tg).

Formula: Bisphenol A Epoxy Resin/ Impact modifier (CSR or CTBN) 0-15wt%/DDS Curing Agent